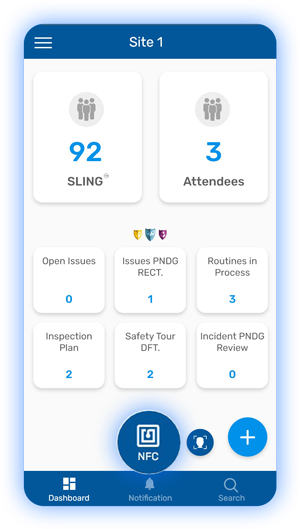

We offer Embedded AI, Ml and IoT technologies to enhance safety data fusion and maximize incident prevention capabilities

Prevention is at the heart of Otoos’s

R&D agenda. The HRSense

core technologies incorporate

the implementation of a ‘physical’

layer of proactive prevention.

This protective layer is deployed when the HRSense technology detects deviations from normal behavior which increases the probability of an accident occurring.

This technology uses an interface between end sensors and cameras that decipher risk scenarios and issue alerts to proactively prevent risk and accidents. The Otoos approach is based on three layers of protection:

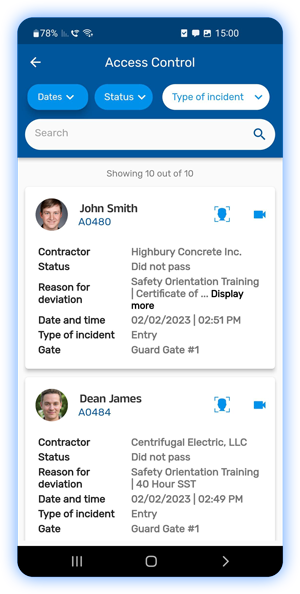

- Access Control

- Real-time Tracking

- Behavior Surveillance